- Products

- Next Generation Sequencing Kits

- Clinic Laboratory

- Laboratory equipment

- Pathology and anatomy

- Analytical & test instruments

- Laboratory consumable

- Diagnostic kits

- Rapid Diagnostic

- Reagents and chemicals

- IVF Products

- Microbiology

- Laboratory furniture

- Kits for Veterinary Medicine

- Promotions

- News

- Service

- About Us

- Careers

- Training

- Contacts

- Product News

- HiSeq 3000/HiSeq 4000

TA Instruments

TA Instruments

TA Instruments

Thermal Analysis

Thermal Analysis is important to a wide variety of industries, including polymers, composites, pharmaceuticals, foods, petroleum, inorganic and organic chemicals, and many others. These instruments typically measure heat flow, weight loss, dimension change, or mechanical properties as a function of temperature. Properties characterized include melting, crystallization, glass transitions, cross-linking, oxidation, decomposition, volatilization, coefficient of thermal expansion, and modulus. These experiments allow the user to examine end-use performance, composition, processing, stability, and molecular structure and mobility.

Differential Scanning Calorimeters

No one sells more DSC’s than TA Instruments. From the most cost-effective DSC with industry leading performance, to the most advanced DSC available, there is a TA Instruments DSC to meet your needs and exceed your expectations.

Differential Scanning Calorimeters (DSC) measures temperatures and heat flows associated with thermal transitions in a material. Common usage includes investigation, selection, comparison and end-use performance evaluation of materials in research, quality control and production applications. Properties measured by TA Instruments’ DSC techniques include glass transitions, “cold” crystallization, phase changes, melting, crystallization, product stability, cure / cure kinetics, and oxidative stability.

TA Instruments’ patented Tzero™ DSC technology, is a revolutionary and fundamentally more accurate way of measuring heat flow. It provides significant improvements in baseline flatness, transition resolution and sensitivity. Tzero™ technology allows direct measurement of heat capacity, and makes Modulated® DSC experiments both faster and more accurate.

Thermogravimetric Analyzers

TA Instruments is the world’s leading supplier of TGA instruments. From the most cost-effective TGA with industry leading performance, to the most advanced TGA available, there is a TA Instruments TGA to meet your needs and exceed your expectations.

TA Instruments invites you to experience the world’s finest line of Thermogravimetric Analyzers, the Discovery TGA 55, TGA 550, and TGA 5500. Discover the advanced engineering and attention to detail that provides enhancements in every aspect of TGA technology and a new level of user experience. From the most cost effective and flexible TGA with industry leading performance, to the most advanced TGA available, there is a Discovery TGA to meet your needs and exceed your expectations.

Microcalorimeters

TA Instruments’ Isothermal Titration Calorimetry (ITC), Differential Scanning Calorimetry (DSC), and Isothermal Calorimetry systems are powerful analytical techniques for in-depth characterization of molecular binding events and structural stability. Thermodynamic binding signatures not only reveal the strength of a binding event, but the specific or nonspecific driving forces involved. Structural stability profiles from DSC reveal strengths and weaknesses in higher order structure and define the behavior of individual domains and their interactions. The TA Instruments Affinity ITC, Nano ITC and Nano DSC provide the performance, reliability and ease-of-use required for the most demanding applications in drug discovery, protein-protein interactions, structure-function characterization and more.

Differential Scanning Calorimetry

TA Instruments’ microcalorimeter DSC’s are powerful tools with unmatched sensitivity for the characterization of molecular structure and molecular stability of in-solution or solid/semi-solid samples.

The Nano DSC and the Multi-Cell DSC represent ultrasensitive differential scanning calorimeters with unmatched flexibility for characterizing molecular structure and stability. The Nano DSC, with fixed-in-place cells, is specifically designed to analyze in-solution samples. The Multi-Cell DSC offers three removable cells and one reference cell for maximum sample flexibility.

View product by category

Nano DSC

Isothermal Microcalorimetry

Based on the pioneering Thermometric technology, our instruments offer maximum sensitivity, flexibility and productivity.

Isothermal Microcalorimetry is an extremely sensitive technique complementary to TA Instruments differential scanning calorimeters. TAM is a microcalorimeter system represented by TAM IV, TAM IV-48 and TAM Air.

Based on the pioneering Thermometric technology, TAM IV offers maximum sensitivity, flexibility, and productivity. It can be used with the most sensitive microcalorimeters and a wide variety of accessories to control the experimental conditions.

View Isothermal Calorimeters

Isothermal Titration Calorimetry

ITC instruments are designed for the most challenging life science laboratory environments that require high sensitivity, high productivity and the most advanced ITC technology.

TA Instruments’ Affinity ITC and Nano ITC series calorimeters perform with the highest sensitivity and unmatched flexibility for the characterization of any molecular interaction. With the best baseline stability available on any ultrasensitive ITC instrument, and the easy-to-use experimental design flexibility, the data quality and reproducibility from these instruments will enhance laboratory throughput with the highest quality results.

View Isothermal Titration Calorimeters

Rheology

Rheology is the study of flow and deformation of materials. Deformation and flow are referred to as strain or strain rate, respectively, and indicate the distance over which a body moves under the influence of an external force, or stress. For this reason, rheology is also considered to be the study of stress-strain relationships in materials.

A rheometer is a precision instrument that contains the material of interest in a geometric configuration, controls the environment around it, and applies and measures wide ranges of stress, strain, and strain rate.

TA Instruments has the world’s most versatile platform for rheological measurements. A full range of environmental systems and measurement accessories are powered by SmartSwapTM Technology for fast exchange & automatic configuration.

Discovery Hybrid Rheometers

The most popular line of rheometers from the World Leader in Rheology.

No other line of rheometers combines state-of-the art patented measurement technology and an unrivaled line of rheometer accessories in an easy-to-use platform.

The Discovery Hybrid Rheometer is available in three models to meet your specific needs of sensitivity and capability. From the world’s most sensitive rheometer – the HR-3 – to general purpose HR-1, every Discovery Hybrid Rheometer is built on a common core of the TA Instruments advanced drag cup motor and second generation magnetic thrust bearing. Find out how the Discovery Hybrid Rheometer will improve your rheological characterization by making better measurements, over a wider range of conditions, with less time in the laboratory.

View Discovery Hybrid Rheometers

ARES-G2

The ARES-G2 is the most advanced rotational rheometer for research and material development.

Dynamic Mechanical Analyzers

No one sells more DMA’s than TA Instruments. Utilizing the latest technological breakthroughs TA Instruments DMA’s provide the best performance and ease-of-use.

Dynamic Mechanical Analysis measures the mechanical properties of materials as a function of time, temperature, and frequency. In addition to basic material properties, DMA also quantifies finished part characteristics, reflecting the important contribution that processing has on end-use performance. DMA is commonly used to measure glass transition temperatures and secondary transitions, orientation caused by processing, cold crystallization, cure optimization, filler effects in composites, and much more. DMA provides an accurate measure of material stiffness (modulus) but also other important mechanical properties such as damping, creep, and stress relaxation.

TA Instruments is the world leader in Dynamic Mechanical Analysis, offering two state-of-the art dedicated DMA instruments and additional DMA capability through our rheometers and mechani-cal test instruments. All TA Instruments DMA products feature innovative technology for force and displacement measurements, temperature control and accuracy, instrument stiffness, and ease-of-use.

Dynamic Mechanical Analyzers

Thermomechanical Analyser Q400 TMA

The Q400 performs high sensitivity mechanical measurements over a wide temperature range.

Rubber Rheometers

RPA

Rubber Process Analyzers

Rubber testing systems with the latest measurement technology for the most accurate, reliable and reproducible data available.

Virtually every aspect of a rubber material’s processing and performance characteristics is influenced by its rheological properties. TA Instruments provides a complete range of rotorless shear rheometers and curemeters to help you optimize processing, curing, and application performance. All TA Instruments rubber rheometers are manufactured to exacting mechanical standards and with the latest measurement technology for the most accurate, reliable, and reproducible data available. Available automation systems allow for maximum unattended laboratory productivity in all test environments. Relevant ASTM, DIN, and ISO standards are easily met, as are demands for advanced testing, making these instruments the ideal choice for quality control, analytical, and research needs.

View Rubber Rheometers

Dilatometers

TA Instruments Dilatometers are high precision systems designed to measure dimensional changes of a specimen brought about by changes in its thermal environment.

Linear thermal expansion coefficient, annealing characteristics and other physical or chemical changes manifesting themselves as a change of dimensions can be precisely determined. Optimization of processing parameters as reflected by dimensional changes of the material can be studied in great detail through duplication of thermal cycles and rates used in the actual process. Due to the flexible programming of thermal cycles, complex processes can be easily simulated.

Horizontal Dilatometers

The best combination of value and performance available on the market.

TA Instruments unique True Differential configuration makes our dilatometers the preferred choice for the high accuracy measurement of coefficient of thermal expansion (CTE). The high precision linear position sensor, the thermostatted measuring head housing and the use of thermally ultra-stable materials all contribute to the outstanding displacement resolution, and ensure the most accurate measurement of low CTE values.

Watch this video to learn more about our complete line of dilatometers.

A complete range of Furnaces rapidly interchangeable by the user, so multiple furnaces can be used with a single instrument, are available to meet the specialized demands of temperature and heating rate.

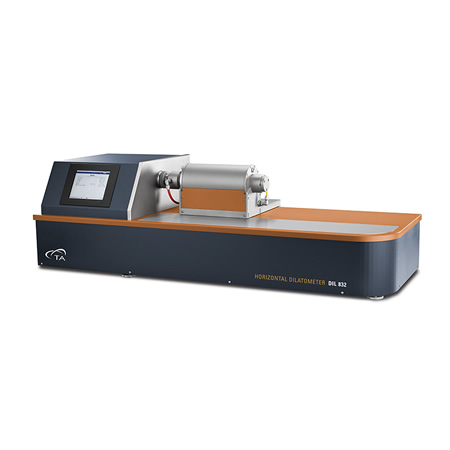

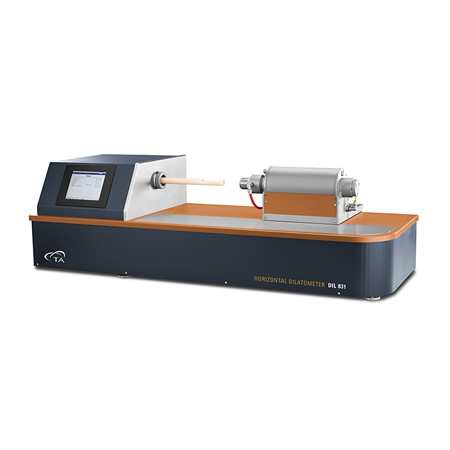

Horizontal Dilatometers

DIL 830 Series

High Resolution Horizontal Dilatometers

High sensitivity optical encoder and best-in-class temperature stability for the most accurate CTE measurements on the market.

This high resolution dilatometry platform offering industry leading Coefficient of Thermal Expansion (CTE) accuracy, the 830 Series features a patented 1nm resolution optical encoder, a family of new dynamic furnaces, and a new linear sample load motor. The result is simply the best performing horizontal push rod dilatomer available on the market.

The 830 Series is an ideal tool for R&D laboratories to measure the linear thermal expansion and to calculate the CTE of polymers, ceramics, glasses, building materials, high performance materials, metals and alloys with exceptional accuracy.

The 830 is available in two different models and a wide selection of high performance and fast cooling furnaces. Additionally, both systems feature our new patented optical encoder that delivers best in class resolution. This, combined with the TA Instrument’s exclusive True Differential™ technology, results in the best sensitivity and CTE accuracy in the industry.

High Resolution Horizontal Dilatometers

DIL 832 True Differential High Resolution Dilatometer

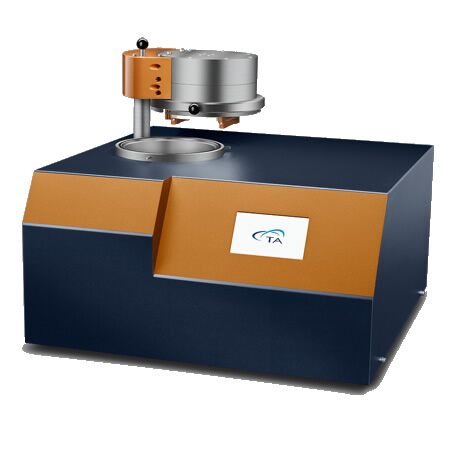

Vertical Dilatometers

The clear choice for sintering study without compromise to temperature uniformity

DIL 820 Series dilatometers operate in a vertical orientation, making it uniquely set up for the analysis of sintering, studies in Rate Controlled Sintering (RCS) mode and the determination of dilatometric parameters of samples otherwise difficult to be analyzed on classic dilatometers with horizontal design. The 820 Series dilatometers are also particularly well suited for powder samples and samples that during the test develop a vitreous phase. That would lead the sample to interact with the sample holder hence generate friction. A major source of errors in the measurament of dilatometric parameters.

All four units feature the new optical encoder with 1nm resolution. That when combined with the True Differential of the DIL822, the result is simply the best possible sensitivity and CTE accuracy on the market.

The vertical orientation also prevents the measuring systems and furnace tubes from sagging when used over long test periods at high temperatures, resulting in extended operational life.

Equipped with a linear motor generating a constant load throughout the experiment, in the 820 Series the pushrod is kept in contact with the sample regardless of dimensional changes.

View Vertical Dilatometers

DIL 820 Series Vertical Dilatometers

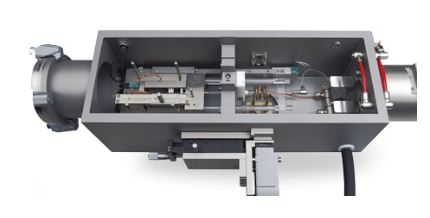

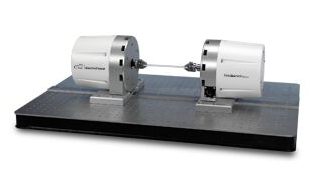

Quenching Dilatometers

Heating rates up to 4000°C/sec and quenching rates up to 2500°C/sec to characterize and optimize of steel and metal alloys processing

Quenching dilatometers allow to study the heat treatment of steel and metal alloys, helping identifying the heating rate, the quenching rate and the isothermal dwell times to be used in metals manufacturing to yield the crystalline structure to necessary to meet the required physical properties.

The related microstructural changes may be observed through process simulation with real-time monitoring of dimensional change. Among other things, measurements of distinct alloy compositions are used to create time-temperature transformation diagrams (TTT) and continuous-cooling transformation diagrams (CCT), which are critical in process design and optimization. With heating rates up to 4000°C/sec and cooling rates of 2500°C/sec, the DIL 805 series quenching dilatometers provide the most accurate measurements over the widest range of heating, cooling and deformation conditions, allowing for the most sophisticated characterization and optimization of metals.

View Quenching Dilatometers

DIL 805A/D Quenching Dilatomers

Optical Dilatometers

Contactless dilatometry for the most accurate and precise expansion measurements and sintering studies.

Optical dilatometry is an innovative and versatile technique capable to measure, without any contact with the sample, dimensional changes in the submicro range and beyond softening point into the melt, hence reproducing real industrial firing cycle conditions.

The contact-less measuring principle of optical dilatometers greatly simplifies sample preparation process because reduces the need of a very precise parallelism between the two ends of the specimen, and the shape of the sample is not as critical as in pushrod dilatometry because the software automatically aligns the optical paths of sample extremities.

Optical Dilatometers

ODP 868 Optical Dilatomery Platform

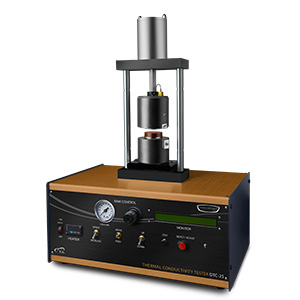

Thermal Conductivity & Diffusivity Meters

We provide the most extensive and comprehensive range of instruments for the precise and accurate measurement of heat transfer properties of a wide range of material types and temperatures.

Thermal conductivity, thermal diffusivity and specific heat capacity define a material’s ability to store and transfer heat. The precise and accurate measurement of these properties is critical for any process or material, which experiences a large or fast temperature gradient, or for which the tolerance for temperature change is exacting.

Insulation & Building Materials

Fox Series Heat Flow Meters

The undisputed market leader in Thermal Conductivity measurement of insulation and building materials.

Our Instruments are reliable, easy-to-use, durable thermal conductivity measurement equipment. Each of our FOX heat flow meters combines advanced sophistication with over 20 years of superior engineering. Search our lineup of thermal conductivity instruments.

The thermal conductivity of a specimen is determined by measuring the heat flux, specimen thickness, and temperature difference across the specimen. In each component of the thermal conductivity equation FOX Instruments provide extremely precise readings, .6mV resolution on integrating high output heat flux transducers, 0.001” precision in thickness measurement, and 0.01°C temperature control and resolution. Each of these individual measurements is an order of magnitude more accurate than any other currently used in thermal conductivity measurement. They combine to provide the most accurate results of any heat flow meter instrument commercially available. When using our high accuracy calibration standard mode, FOX Instruments challenge and exceed the accuracy of the enormously time consuming, operator dependent, and expensive guarded hot plates.

Insulation & Building Material Test Instruments

Fox 801

Fox 600 GHP

The most intuitive solution to test materials in accordance with international standard test methods ASTM C177, ISO 8302, and EN 12667.

General Purpose Heat Flow Meters

The most complete product for thermal conductivity measurement from 0.1 up to 40 W/mK.

Thermal conductivity defines a material’s ability to transfer heat. Its precise and accurate measurement is critical for any process or material, experiencing large or fast temperature gradients, or for which the tolerance for temperature changes is exacting. Accurate values are essential for modeling and managing heat, whether the component of interest is called on to insulate, conduct, or simply withstand temperature changes. Information about these properties are routinely used in heat transfer models of all complexities. Thermophysical property measurements also reflect important information about material composition, purity and structure, as well as secondary performance characteristics such as tolerance to thermal shock.

Our Heat Flow Meters DTC Series and Fox 50 Series provide the solution to a highly diverse set of testing needs for the direct measurement, according to a large number of ASTM, ISO and EN standard methods, of thermal conductivity of low to medium conductivity materials.

General Purpose Heat Flow Meters

DTC 25

Thermal Diffusivity is the thermophysical property that defines the speed of heat propagation by conduction during changes of temperature. The higher the thermal diffusivity, the faster the heat propagation.

TA Instruments offers the most compelling range of instruments measuring the thermal diffusivity by the flash method from -150°C up to 1600°C. All systems include multiple specimen testing capability that provides several times increase in productivity. Full time pulse mapping, precision optics, and the latest data analysis models make the Discovery Flash platform the most accurate and precise system of its kind.

Laser Flash Instruments (DLF)

Xenon Flash Instruments (DXF)

ElectroForce Mechanical Test Instruments

We start with your specific testing needs and combine unique ElectroForce motor technologies with our test applications engineering expertise to create a tailored test solution that meets your testing objectives. After you buy a TA Electroforce product, you become a valued, lifelong customer. Providing exceptional, ongoing support is our commitment to you.

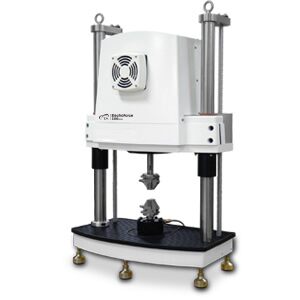

ElectroForce Load Frame Instruments

ElectroForce technologies have revolutionized the way material testing is performed. Available in a range of force capacities, from 22 N up to 15 kN, ElectroForce load frame instruments provide industry leading performance, versatility, and durability.

The design of new materials and products requires a thorough assessment of material properties and complete performance evaluation within, and sometimes beyond, the intended end-use.

TA ElectroForce® test instruments, featuring proprietary ElectroForce linear motion technologies and WinTest® controls, provide a revolutionary approach to mechanical fatigue and dynamic characterization. The ElectroForce family of load frame test instruments includes a full range of force and performance capabilities for a wide variety of test applications. ElectroForce test instruments are also very lab-friendly thanks to their practically maintenance-free operation. As a result, they have set a new standard for performance, simplicity and versatility in a single test instrument.

View Load Frame Instruments

ElectroForce 5500

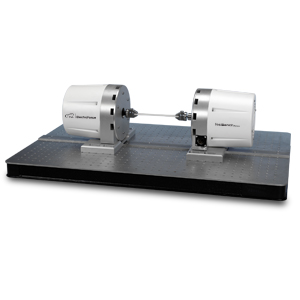

TestBench & Planar Biaxial

Test Instruments

Industry-leading performance and durability in a modular and user-configurable platform. These instruments enable unique and user-adjustable configurations for a wide variety of tests.

TestBench configurations were designed with component testing in mind, and thanks to their modular approach, a wide array of configurations and performance capabilities are possible. TestBench systems can be multi-channel and multi-axis, including planar biaxial testing.

View TestBench and Planar Biaxial Test Instruments

Planar Biaxial

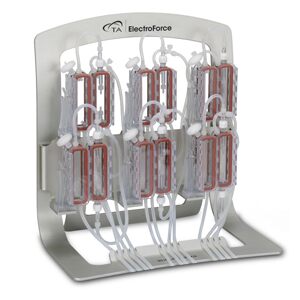

ElectroForce Cardiovascular

Test Instruments

From bare metal stents to heart valves to pacemaker components, we offer the most comprehensive portfolio of cardiovascular device testing solutions. For more than 20 years, medical device manufacturers have trusted ElectroForce as the world leader in accelerated fatigue test instruments.

Now, you can replicate years of device life in a matter of weeks. Whether you want to determine the durability limits of a device component or characterize an entire structure, ElectroForce cardiovascular device test instruments support the advancement of your research and product development activities by testing at accelerated frequencies, reducing the testing time that is needed to meet international regulatory requirements.

Multi-Specimen Fatigue

Tissue Engineering Instruments

From introductory bioreactors to the most versatile mechanical stimulation bioreactors on the market, ElectroForce BioDynamic instruments are engineered to advance 3D tissue growth.

TA ElectroForce® BioDynamic® test instruments combine bioreactor chambers with mechanical test instruments to provide stimulation, characterization, and tissue growth solutions for engineered tissues and biomaterials within a sterile cell culture media environment.

Available in single or multi-chamber configurations, BioDynamic test instruments simulate in vivo conditions and bridge the gap between basic in vitro exploratory studies in culture dishes and in vivo animal experiments. For cell growth and 3D tissue culture that does not require mechanical stimulation, the 3DCulturePro bioreactor is an easy-to-use solution that will provide researchers with the reproducible results they are looking for.

View BioDynamic Instruments

BioDynamic 5200

ElectroForce Dynamic Mechanical Analyzers

ElectroForce versatility extends to Dynamic Mechanical Analysis (DMA) by configuring almost any ElectroForce instrument with DMA Accessories.

Several TA ElectroForce® test instruments are well-suited for DMA analysis and QA testing of viscoelastic materials such as elastomers, polymers, composites and tissues. The wide frequency and loading ranges of ElectroForce instruments align well with the dynamic nature of DMA tests. In addition, their compact designs and quiet, clean and durable operation allow them to be used in virtually any environment, from processing floor to clean room to tissue culture incubator.

The following ElectroForce instruments can be configured for Dynamic Mechanical Analysis including Temperature Analysis.

| Model | Maximum Force (N) | Max DMA Frequency (Hz) | Temperature Range (C) |

| 3200 | 450N | 200Hz | -150 to 315C |

| 3300 | 3000N | 75Hz | -150 to 350C |

| 3510 | 7500N | 40Hz | -150 to 350C |

| 3550 | 15000N | 35Hz | -150 to 350C |

The following ElectroForce instruments can be configured for Dynamic Mechanical Analysis at ambient or 37C temperature.

| Model | Maximum Force (N) | Max DMA Frequency (Hz) | Temperature Range (C) |

| 3100 | 22N | 75Hz | Ambient air or 37C fluid |

| 200N TestBench | 200N | 75Hz | Ambient air or 37C fluid |

| 200N Planar Biaxial | 200N | 75Hz | Ambient air or 37C fluid |

| 5500 | 200N | 15Hz | Ambient air or 37C fluid |

| 5100 BioDynamic | 200N | 10Hz | Ambient air or 37C media |

ElectroForce Dynamic Mechanical Analysis Instruments

Rubber Testers

TA Instruments introduces a complete line of new instruments for the measurement of rheological and physical properties of polymers, rubber and rubber compounds at all stages of manufacture. The new rubber testing instruments include a Rubber Process Analyzer, Moving Die Rheometer, Mooney Viscometer, Automated Density Tester and Automated Hardness Tester.

All TA Instruments rubber testing systems are manufactured to exacting mechanical standards and with the latest measurement technology for the most accurate, reliable and reproducible data available.

RPA

Rubber Process Analyzers

Rubber testing systems with the latest measurement technology for the most accurate, reliable and reproducible data available.

Virtually every aspect of a rubber material’s processing and performance characteristics is influenced by its rheological properties. TA Instruments provides a complete range of rotorless shear rheometers and curemeters to help you optimize processing, curing, and application performance. All TA Instruments rubber rheometers are manufactured to exacting mechanical standards and with the latest measurement technology for the most accurate, reliable, and reproducible data available. Available automation systems allow for maximum unattended laboratory productivity in all test environments. Relevant ASTM, DIN, and ISO standards are easily met, as are demands for advanced testing, making these instruments the ideal choice for quality control, analytical, and research needs.

View Rubber Rheometers

Mooney Viscometer

Mooney Viscometer incorporates the latest measurement technology for the traditional Mooney viscosity, Mooney scorch, and stress relaxation measurement in the rubber industry.

Density & Hardness Testers

The TA Instruments Automated Hardness tester and Automated Density tester streamline the measurement of cured rubber physical properties. These fully automated instruments test up to 30 samples for sequential, reliable, unattended measurement. Software-driven test set-up, data collection, and pass/fail criteria make these systems truly automated.

View Density and Hardness Testers

AHT – Automated Hardness Tester

Sample Cutter

Sample preparation for RPA, MDR, and Mooney instruments is made safe and simple with the VS volumetric sample cutter.